How fantastic is this? The C+P has a bit of original pinstriping! Sadly, I don’t think we can save it since there’s also bare metal which needs to be protected. This means a coat or two of paint which will cover those swirls of gold. Maybe once it’s painted we can finish it off with new pinstriping!

press restoration

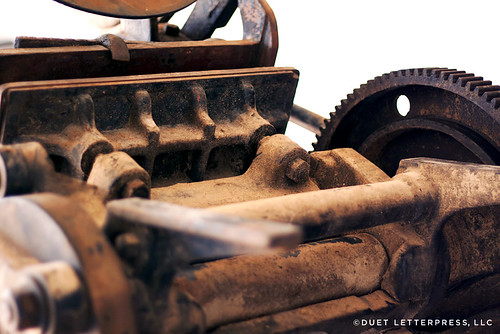

ppr3 // dusty past

Our second press had a colorful past. This one has a dusty one.

The previous owner has a sand carved sign business.

And, the last twenty-something years, this press sat in his huge garage.

For every one of those years, a layer of sawdust seems to have been added to the press.

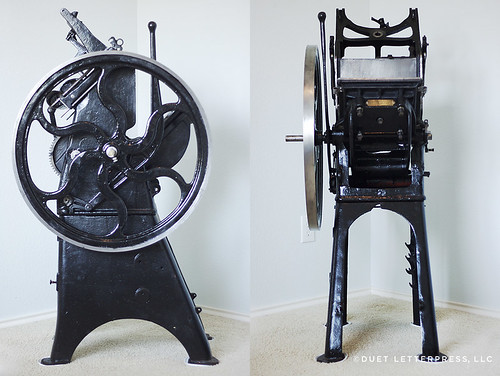

project press restoration 3 // parts

We’re about to get our hands dirty and tackle our third press. Like our previous Pearls, we will be cleaning, priming and painting our Old Style C&P 10×15.

As we go along, I’ll be documenting it all here. I’ll be calling it Project Press Restoration 3, PPR3 for short. To make it easier to follow along, I’ve added a new press restoration blog category to contain all of the posts. This new category also includes posts from our previous restoration projects – our first + second Pearl presses.

In addition to cleaning, priming + painting our C&P, we will also be sourcing parts to convert it to a treadle-operated press. And, there are a couple of parts that it didn’t come with but we will need for printing, so we will be sourcing those, too. Here’s a list of the parts we need. Except for the base + rollers, we hope to find originals.

- platen

- rollers

chase- treadle

- treadle connecting parts

- Boxcar base

- side feed board

This particular press was used for die cutting. It didn’t have a chase and the platen is pretty chewed up because a jacket wasn’t used for the die cutting. We will either be machining down the platen or getting another one to replace it. Right now we’re assessing the damage and working on price quotes for each option.

I’ve already crossed out #3 because an original Old Style chase has been tracked down, ordered and should be coming in very soon.

We have a lot of work ahead of us but we are very excited about the challenge. We’re looking forward to it being finished and printing away in our studio!

chandler & price

How was your weekend? Ours was super busy. We printed, brought Em to a pumpkin patch and took a road trip to pick up that Chandler & Price press. The move went so smoothly. Best case senario really. And I’m so relieved. The press is now residing in our garage waiting to be cleaned up + painted. Again, we have quite the press restoration project on our hands!

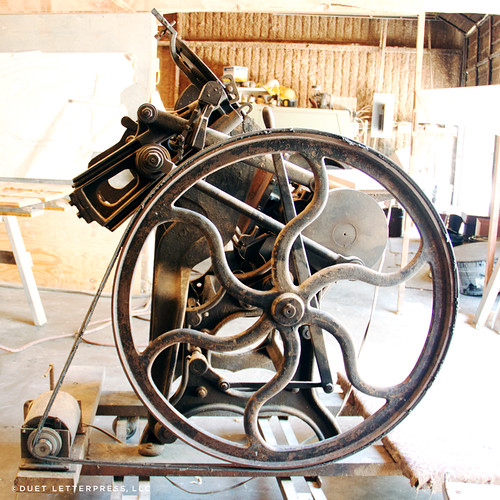

old style c&p

This weekend, Kacey, Em and I took a look at a handful of presses for sale. This is one of them. An old style C&P. Although it’s quite dirty and will need some restoration work, it seems to be in good shape structurally. We have a bit more research + thinking to do before we determine if this is the right press for us. It would definitely be a large jump from our little Pearl but that’s what we’re searching for.

restoring our second pearl // finished. done.

For nearly a year, we poured ourselves into our second Pearl press. Stripping, sanding, priming, painting, repainting, sourcing parts. This weekend, all the parts were in. The brand new rollers. An original crank. A new connecting rod. Everything was in our hands. Saturday night, our press was finished. Done.

Only, if you follow us on twitter, you know those words have a much different meaning than we could have ever dreamed.

After the last bolt was in place, we added packing, put on a plate and spun the wheel. On about the third spin, there was a deep + loud pop. Kacey slowly spun the wheel again inspecting the mechanics of the press. He took a look at the paper it had just printed. The impression wasn’t even. He looked on the side of the press and there it was. A crack clean down the body of the press.

All of that hard work. All of the money. Gone. The crack too significant and beyond repair. And we never saw it coming. It spun fine all along. Saturday night, though, adding the packing and the pressure of the plate just did it in. We are heartbroken.

It’s finished. Done.

restoring our second pearl // progress

So, we’re restoring our second new-to-us Pearl Press. If you recall, we’ve cleaned, stripped, sanded, primed and painted it with a gleaming coat of black paint. After doing so, we realized it was way too glossy, especially compared to our first Pearl Press. Knowing that they’d be side by side in our studio, we decided to repaint it with a semi-gloss paint. Kacey spent a few weekends repainting the press and this weekend we finally got it reassembled and in our studio! So exciting. We have a few more parts to source before it’s going to be fully up and running. We need to find or fab parts to convert it from a motor operated to a treadle operated press. We’re also going to be making new feeder boards. Plus, we’re waiting on new rollers, cores + trucks but they’re already ordered. Oh, we’re so, so close!

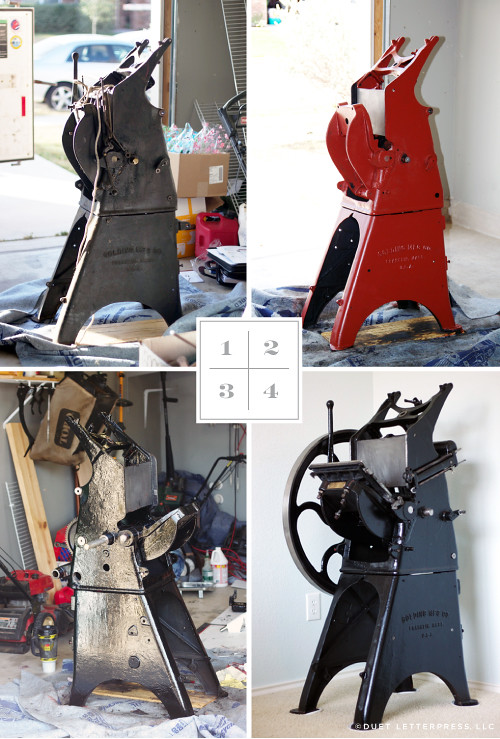

one – original / two – primed / three – gloss paint / four – semi-gloss paint